Description

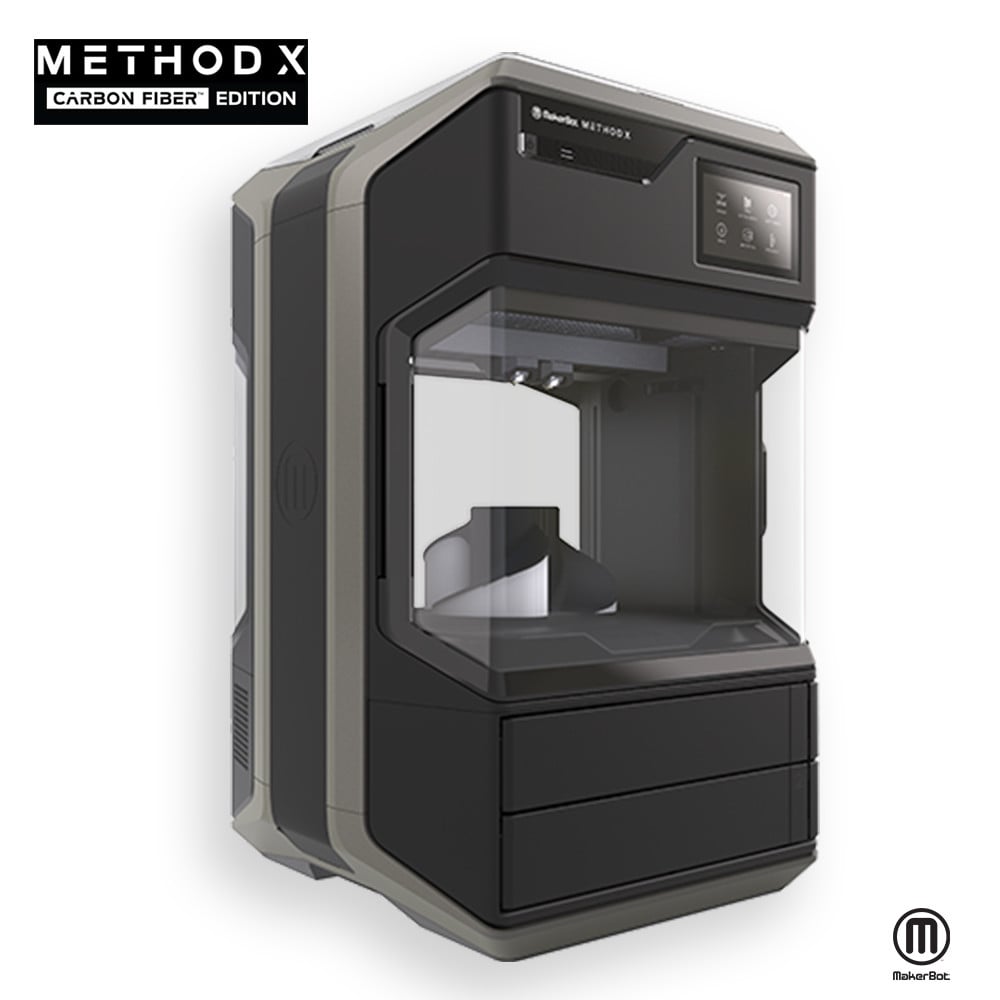

900-0001A MakerBot METHOD 3D Printer

900-0064A Composite Extruder for MakerBot METHOD

MakerBot Method Carbon Fiber Edition:

New to MakerBot in 2020! The MakerBot Method/X Carbon Fiber Edition. Print carbon fiber reinforced nylon and other engineering-grade composite parts with three-dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform. This printer is ideal for anyone that needs to produce strong and accurate parts.

Print carbon fiber reinforced nylon and other engineering-grade composite parts with three dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform.

WHAT’S IN THE BOX:

METHOD 3D Printer

Model 1c Composite Extruder

Support 2 Extruder

SUPPORT MATERIAL COMPATIBILITY:

PVA

MODEL MATERIALS SUPPORTED:

Nylon Carbon Fiber

PLA

Tough

PETG

Nylon

REPLACE METAL PARTS WITH 3D PRINTED CARBON FIBER:

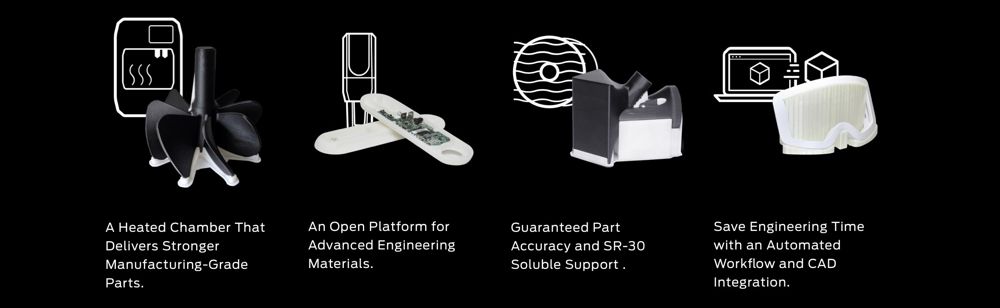

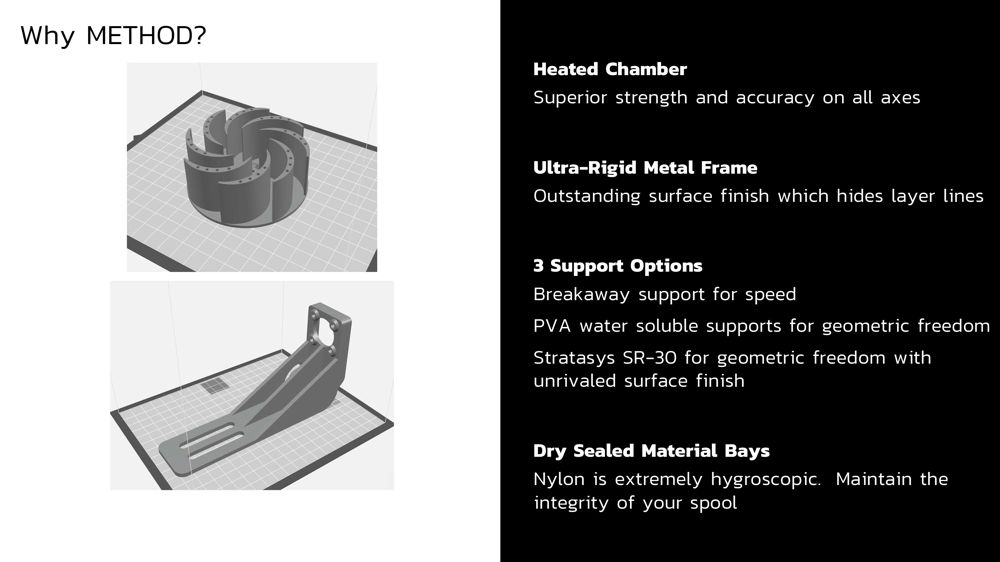

Performance: Heated chamber that delivers stronger manufacturing-grade parts

Precision: Consistent, repeatable and accurate parts time after time

Flexibility: An open platform for advanced engineering materials

Usability: Simple intuitive user interface

Key Uses: Jigs and fixtures, Manufacturing Tools, and some end-use production components.

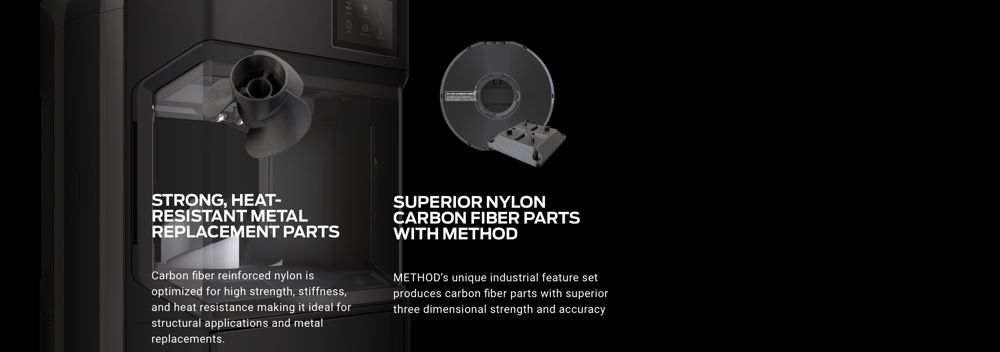

STRONG, HEAT-RESISTANT METAL REPLACEMENT PARTS:

Carbon fiber reinforced nylon is optimized for high strength, stiffness, and heat resistance making it ideal for structural applications and metal replacements.

Excellent strength to weight ratio – 110 MPa TS – for lightweighting applications such as robotic end effectors

Engineering-grade stiffness – 7600 MPa Tensile Modulus – for structural applications such as vehicular brackets and inspection gauges

High heat resistance under load – 184°C HDT – for optimal under-hood and tooling applications

SUPERIOR NYLON CARBON FIBER PARTS:

METHOD’s unique industrial feature set produces carbon fiber parts with superior three-dimensional strength and accuracy.

METHOD’s Heated Chamber delivers parts that are strong and and accurate.

Outstanding surface finish that hides layer lines thanks to METHOD’s Ultra-Rigid Metal Frame.

Print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability, and METHOD’s pre-print spool drying feature allows for the recovery of oversaturated filament.

APPLICATIONS:

Manufacturing Tools

End Use & Replacement Parts

High Strength Structural Components

PROPERTIES:

Excellent strength to weight ratio

Engineering grade stiffness

High heat resistance – 186°C Heat Deformation temperature

KEY FEATURES:

Circulating heated chamber

Includes MakerBot Composite & Support Performance Extruders

Dry-sealed Material Bays

Pre-Print Material Drying

Post-Wash Part Annealing

Ultra-Rigid Metal Frame

MakerBot Cloud Connected

SPECIFICATIONS:

CHAMBER TEMPERATURE: METHOD: 60°C | METHOD X 110°C

DIMENSIONAL ACCURACY ± 0.2mm / ±0.007in 1

LAYER RESOLUTION Maximum Capability: 20 – 400 micron

BUILD VOLUME: Single Extrusion 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in Dual Extrusion 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in

POWER REQUIREMENTS METHOD 100 – 240 V 3.9A – 1.6A, 50/60 Hz 400 W max. METHOD X 100 – 240 V 8.1A – 3.4A, 50/60 Hz 800 W max.

Technical Specification

Dimensional Accuracy ± 0.2mm / ±0.007in

Layer Resolution Maximum Capability: 20 – 400 micron

Product Dimensions & Weight

43.7 L x 41.3 W x 64.9 H cm

17.2 x 16.3 x 25.6 in

29.5 kg / 65 lbs

Maximum Build Volume

Single Extrusion

19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in

Extruders Dual Performance Extruders

(Model & Support)

Build Surface Spring Steel Build Plate with Grip Surface

Material Storage Dry-Sealed Material Bays plus sensors for

humidity and temperature.

Supported Materials Tough PLA, PLA, PVA, Carbon Fibre, Nylon,PET-G+ more support materials coming soon…

Connectivity WiFi, Ethernet, USB drive

Power Requirements 100-240V 4A, 50-60Hz 400 W max

Standard Warranty 12-months on-site- upgradeable to 3-years at extra cost.