MakerBot METHOD X 3D Printer – Carbon Fiber Edition

900-0002A MakerBot METHOD X 3D Printer

900-0064A Composite Extruder for MakerBot METHOD

900-0013A Support 2 Extruder for MakerBot METHOD

$5,999.00

CARBON FIBER MADE ACCESSIBLE

Replace metal parts and assemblies with 3D printed Carbon Fiber and dissolvable supports

ABS, FINALLY AS EASY AS PLA

With our proprietary RapidRinse™ support, achieve incomparable ABS parts with unprecedented ease.

TAP WATER SOLUBLE

Forget the cumbersome wash tanks and chemicals, RapidRinse™ dissolves in pure tap water so it’s easy to use in just about any environment.

DISSOLVES IN MINUTES*

You don’t have time to wait around while your print dissolves, so we’ve engineered RapidRinse™ to dissolve faster than PVA and competitive high-temp dissolvable support materials.

*Dissolution time may vary based on part geometry and dissolution methodology

900-0002A MakerBot METHOD X 3D Printer

900-0064A Composite Extruder for MakerBot METHOD

900-0013A Support 2 Extruder for MakerBot METHOD

MakerBot Method X Carbon Fiber Edition:

New to MakerBot in 2020! The MakerBot Method/X Carbon Fiber Edition. Print carbon fiber reinforced nylon and other engineering-grade composite parts with three-dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform. This printer is ideal for anyone that needs to produce strong and accurate parts.

Print carbon fiber reinforced nylon and other engineering-grade composite parts with three dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform.

WHAT’S IN THE BOX:

METHOD X 3D Printer

Model 1c Composite Extruder

Support 2XA Extruder

Support 2 Extruder

SUPPORT MATERIAL COMPATIBILITY:

All official MakerBot Model & Support Material

To extend extruder life we recommend not switching between METHOD & METHOD X materials with one model extruder

REPLACE METAL PARTS WITH 3D PRINTED CARBON FIBER:

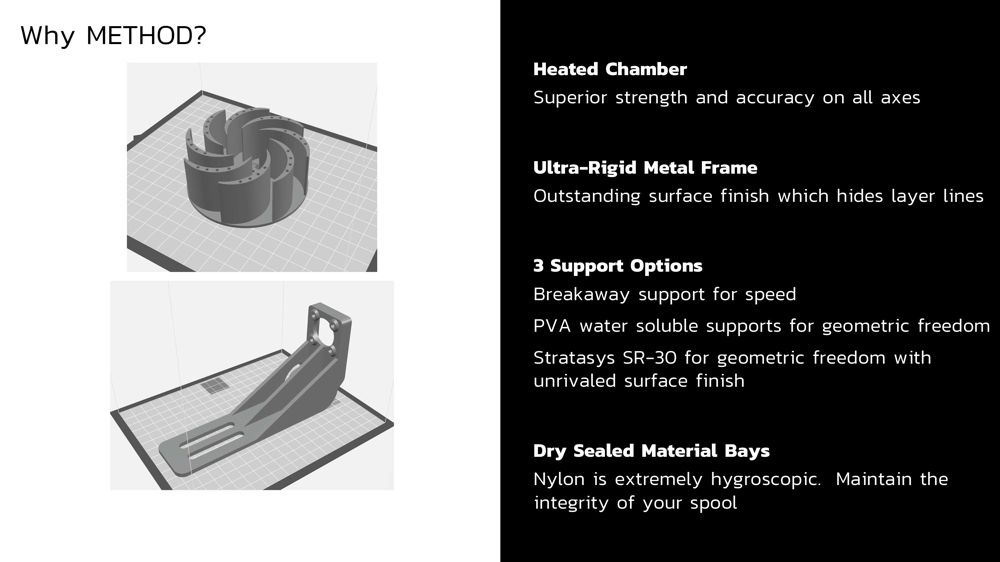

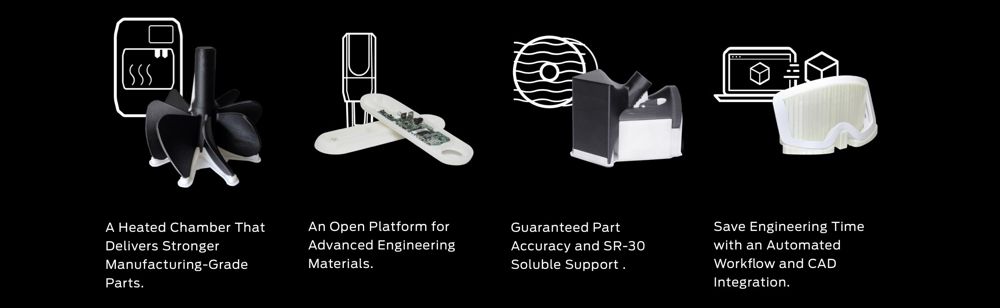

Performance: Heated chamber that delivers stronger manufacturing-grade parts

Precision: Consistent, repeatable and accurate parts time after time

Flexibility: An open platform for advanced engineering materials

Usability: Simple intuitive user interface

Key Uses: Jigs and fixtures, Manufacturing Tools, and some end-use production components.

STRONG, HEAT-RESISTANT METAL REPLACEMENT PARTS:

Carbon fiber reinforced nylon is optimized for high strength, stiffness, and heat resistance making it ideal for structural applications and metal replacements.

Excellent strength to weight ratio – 110 MPa TS – for lightweighting applications such as robotic end effectors

Engineering-grade stiffness – 7600 MPa Tensile Modulus – for structural applications such as vehicular brackets and inspection gauges

High heat resistance under load – 184°C HDT – for optimal under-hood and tooling applications

SUPERIOR NYLON CARBON FIBER PARTS:

METHOD’s unique industrial feature set produces carbon fiber parts with superior three-dimensional strength and accuracy.

METHOD’s Heated Chamber delivers parts that are strong and and accurate.

Outstanding surface finish that hides layer lines thanks to METHOD’s Ultra-Rigid Metal Frame.

Print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability, and METHOD’s pre-print spool drying feature allows for the recovery of oversaturated filament.

We’ll send onboarding instructions, tips, and videos to get you started printing reliable parts straight out of the box with METHOD

With over 25 videos and over 100 articles, our team has all the content you need to keep printing high quality parts in a variety of materials on METHOD.

Whether you prefer phone, email, or live chat, MakerBot support experts are just a step away.

HEATED CHAMBER TEMPERATURE:

110° C Maximum Temperature

BUILD VOLUME:

Dual extrusion: 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in

Single extrusion: 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in

OVERALL DIMENSIONS

41.3 L x 43.7 w x 64.9 H cm

Please note: MakerBot materials sold separately.

| Weight | 65 lbs |

|---|---|

| Dimensions | 17.2 × 16.3 × 25.6 in |

Free ground shipping on orders all $99 and up.

We are an authorized dealer for every brand we sell.

Special pricing for preffered customers and dealers.

We are projector experts, with over 20 years of service.

From projectors to projection screens, digital signage to gaming equipment, PSSAV is Your number one source for audio visual equipment. over 200 top brands including Sony, Nec, Epson, Optoma, Benq, Chief, Dalite, Viewsonic, LG and more..